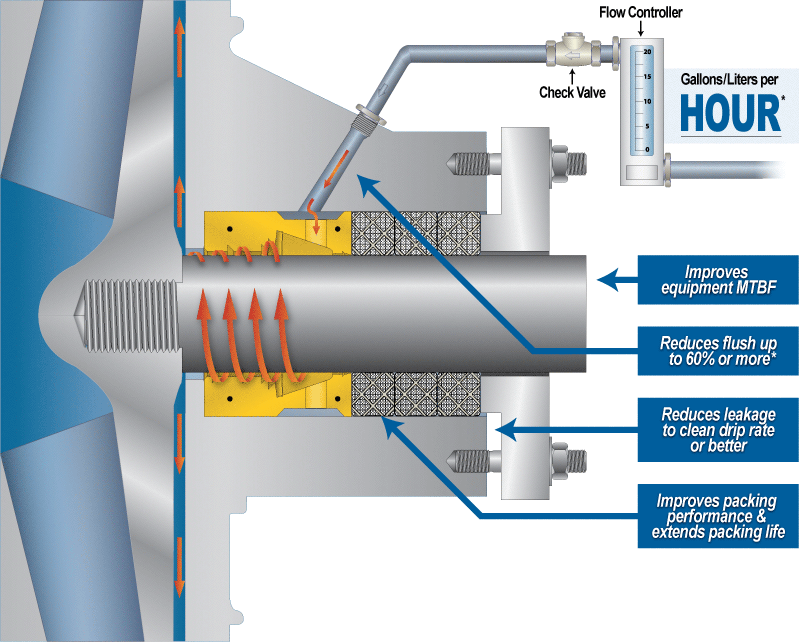

Highly dependant on application, but typically you can expect a reduction of 60%-80% flush rate needed for successful operation. Please note, SpiralTrac does not reduce flush on its own, it allows the application to run successfully with a reduced flush rate! EnviroSeal always recommends the use of flow controller and check valve when installing SpiralTrac.

This room is dependant on the distance of your first obstruction. If this distance is shorter than the SpiralTrac needed we may be able to manufacture SpiralTrac in multiple axial pieces.

Typically, no, you will need less rings of packing after installing SpiralTrac. For example, in the commonly used 2L3 setup SpiralTrac replaces the bottom 2 rings of packing and the lantern ring so instead of 5, you will only need 3 rings of packing.

No, our standard Packing Version SpiralTrac reduces the amount of flush needed to run the application successfully. To achieve flush reduction EnviroSeal recommends the use of flow controller and check valve.

Yes. SpiralTrac is designed to replace any packing-lantern ring configurations.

Typically, No. The SpiralTrac is designed to inserted from the gland side of the stuffing box with a locational clearance fit. The rings of packing and the gland follower keeps the device in place.

No. However, if you are changing the packing and time is available, you can remove, inspect, clean and reinsert the SpiralTrac before replacing the packing. When inspecting the device make sure there is no obstruction in the spiral and the flush holes.

Yes. We recommend choosing your packing based on operating conditions. All packing should be broken in according to manufacturer specifications.

There are a number of methods to ensure the SpiralTrac Version P is installed correctly:

There is an installation label indicating the impeller side of the device (which should be removed prior to installation).

Rotation direction is engraved on the lantern ring section.

The part number is engraved on the impeller end of the SpiralTrac.

The tangential hole will inject the flush in the direction of shaft rotation.

The puller holes that facilitate the removal of the device should be facing the gland.

Typically, we recommend a minimum of 3 rings of packing above the SpiralTrac. However many times, mostly in low pressure applications, we have successfully used SpiralTrac with only 2 rings of packing.

MGE (PPS blend thermoplastic), BGE (PEEK blend thermoplastic) and 660 Bronze.

Yes. As this is still a packed application, the gland follower would be tightened just beyond finger tight. Adjustments are still going to be necessary however they should be less and fewer in between. We often come across applications where 6 or more months go by in between adjustments.

The required flush pressure is dependent on the stuffing box pressure. Normal flush pressure should be above box pressure by a minimum of 1 Bar / 14.5 PSI, enabling the flush to push any contaminants under the existing throat.

Depends on where the sleeve is worn. SpiralTrac can function properly over a worn sleeve. It is very important that the sleeve area under the packing outboard of the SpiralTrac is in good condition.

The minimum axial length of Packing Version SpiralTrac is 1”/25.4 mm.

These devices are designed to be easily installed in the field where the required upgrades associated with the air vent cannot be done. The use of flush also takes care of the air trapped in the stuffing box.

The Packing Version SpiralTrac typically has puller holes on the gland side of the device to facilitate the starting of a packing extractor. For more information please refer to the installation instruction.

Yes, both split and non-split Packing Version SpiralTracs are available in metal.

No. All Packing Version SpiralTracs require flush to force the contaminants under the existing throat.

Solution: packing

Application: Coal Ash

Equipment: Clinker Grinder & Diamond Power Pump

Solution: packing

Application: Pulp

Equipment: Sprout Bauer Model 489-23

Solution: packing

Application: Paper Stock

Equipment: Vertical Hydropulper, 370 Heat Dissipating Packing, Packing Version SpiralTrac, S50 Flow Guardian

Moves the packing down the shaft

Prolongs shaft/sleeve life

Drastically reduced flush rates

Aside from the original, EnviroSeal offers it's highly popular Version P device in three modified configurations. Check them out below.

Shaft deflection and vibration contribute to premature packing and seal failure

Tight clearance for added shaft support.

Faster, easier, more effective maintenance

Minimizes heat buildup